What These Projects Will Deliver

Once up and running, the new units will generate components worth ₹36,559 crore. More than 5,100 people will get direct jobs in these plants. The factories are spread across Tamil Nadu, Andhra Pradesh and Madhya Pradesh, so the growth is not just stuck in big cities.

Union Minister for Electronics and IT, Ashwini Vaishnaw, shared that these plants will fully meet the country’s need for copper clad laminates. They will also cover 20 percent of the local demand for printed circuit boards and 15 percent for camera modules. On top of that, around 60 percent of whatever these units make will head overseas as exports.

Key Components Coming Out of Indian Factories

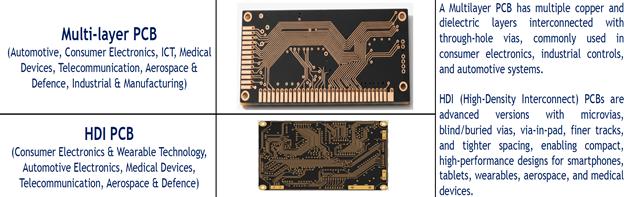

The approved projects focus on high-density interconnect PCBs, multi-layer PCBs, camera modules, copper clad laminates and polypropylene films. These are the building blocks of almost every gadget we use daily.

Camera modules are tiny units that snap pictures and record videos in phones, drones, laptops, medical gear and even cars. Making them locally means faster supply for Indian brands and lower costs.

Printed circuit boards act like the nervous system of any electronic device. They connect chips, sensors and other parts. Until now, most high-end boards came from abroad. These new plants change that.

Copper clad laminates form the base layer for multi-layer PCBs. Setting up a full facility for this material is a first for India. It ends our complete reliance on imports for this crucial raw item.

Polypropylene films go into making capacitors, which store and release energy in circuits. You find them in everything from TVs and cars to telecom towers and solar panels.

Why This Matters for Everyday Indians

Think about your phone or laptop. Right now, many tiny parts inside travel thousands of kilometres before reaching the assembly line. That adds cost and delays. Local production brings prices down and makes repairs easier.

More factories mean more skilled jobs. Engineers, technicians and researchers will find work close to home. These roles pay better and need training, so young people in smaller towns get a real shot at tech careers.

Defence gear, electric vehicles, telecom networks and solar plants all need reliable parts. When we make them ourselves, we control quality and supply. No more waiting for shipments during global shortages.

How the Scheme Attracted So Much Interest

Companies from India and abroad flooded the scheme with applications. In total, 249 proposals landed on the table, promising ₹1.15 lakh crore in investments. If all go through, they could produce goods worth ₹10.34 lakh crore and create 1.42 lakh jobs. That is the biggest commitment ever seen in Indian electronics.

The seven projects cleared today are just the start. They show the scheme works and more will follow. Tamil Nadu gets five units, Andhra Pradesh one and Madhya Pradesh one. This spread helps every region grow its tech base.

Bigger Picture for Indian Manufacturing

India already assembles phones and TVs in large numbers. Now the focus shifts deeper, to modules, chips and even raw materials. The Electronics Components Manufacturing Scheme fits perfectly with the Production Linked Incentive plans and the India Semiconductor Mission.

Together, these efforts build a complete chain. Designers dream up products here, factories make every layer from silicon to packaging, and finished goods ship out to the world. Exports earn foreign exchange, jobs stay local and innovation gets a permanent home.

Lower import bills free up money for roads, schools and hospitals. Cheaper electronics put better gadgets in more hands. Students learn on laptops, farmers use drones, doctors get affordable scanners. The ripple effect touches every corner of life.

The road ahead looks busy. More approvals are in the pipeline. Companies are scouting land, hiring trainers and ordering machines. Within a couple of years, shelves in global stores could carry proudly Indian components. That is the kind of self-reliance the country has been working towards.

For anyone tracking tech growth, this is a milestone worth watching. Local parts mean stronger startups, tougher defence systems and greener energy solutions. The first seven projects are live proof that India can design, build and ship world-class electronics.

Focused keyword: Electronics Components Manufacturing Scheme

Meta description: Electronics Components Manufacturing Scheme gets ₹5500 crore boost with 7 projects to produce PCBs, camera modules, create 5100 jobs and cut imports.